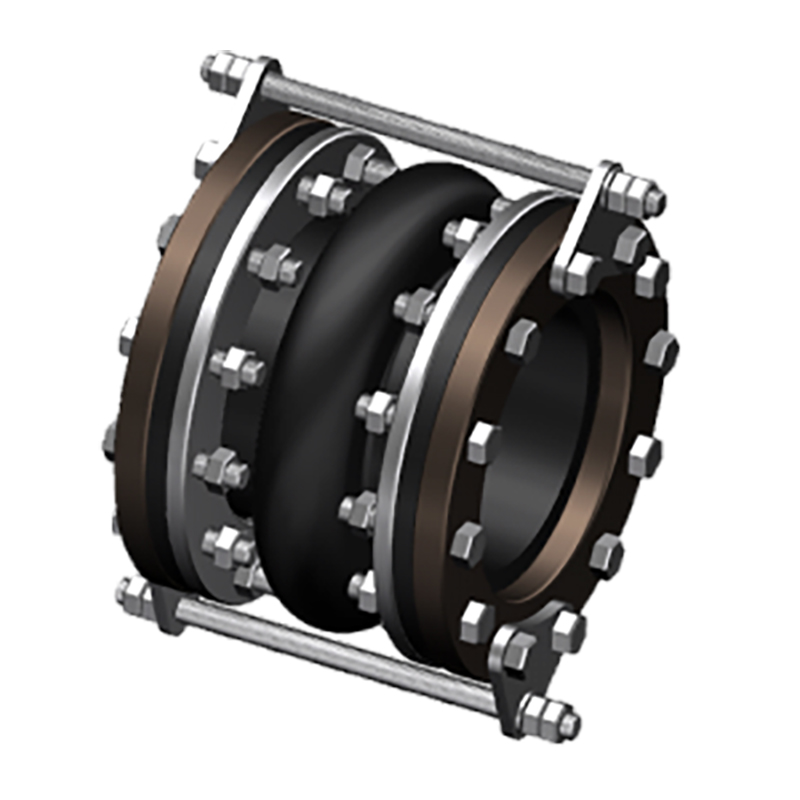

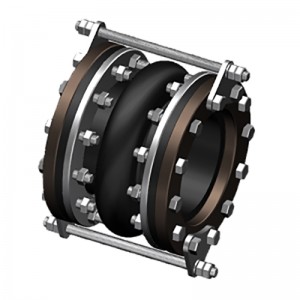

Supply ODM China Cast Iron dismantling joint for municipal water Pipeline

We constantly stick to the theory “Quality To start with, Prestige Supreme”. We have been fully committed to offering our consumers with competitively priced quality products and solutions, prompt delivery and qualified service for Supply ODM China Cast Iron dismantling joint for municipal water Pipeline, We warmly welcome buddies from all walks of everyday living to hunt mutual cooperation and build a more brilliant and splendid tomorrow.

We constantly stick to the theory “Quality To start with, Prestige Supreme”. We have been fully committed to offering our consumers with competitively priced quality products and solutions, prompt delivery and qualified service for China Dismantling Joint, Universal Dismantling Joint, We now have a good reputation for stable quality products and solutions, well received by customers at home and abroad. Our company would be guided by the idea of “Standing in Domestic Markets, Walking into International Markets”. We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

Details

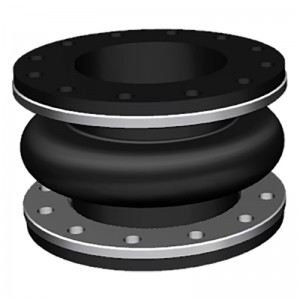

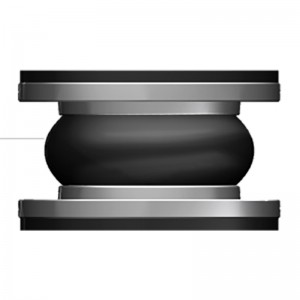

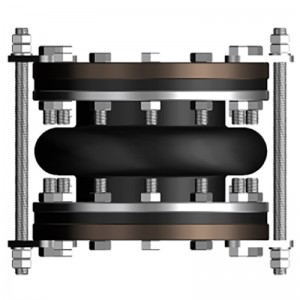

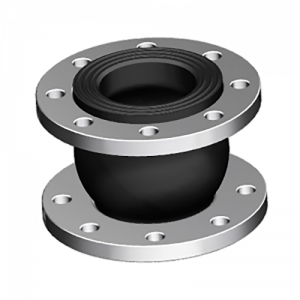

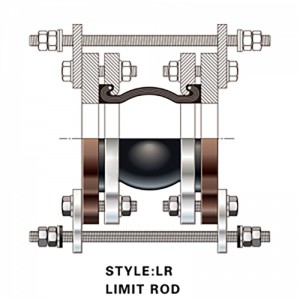

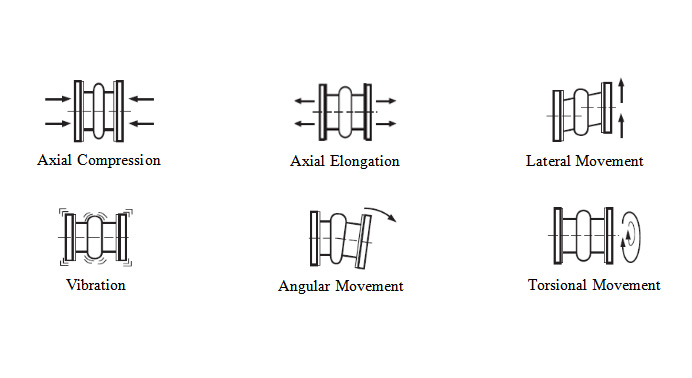

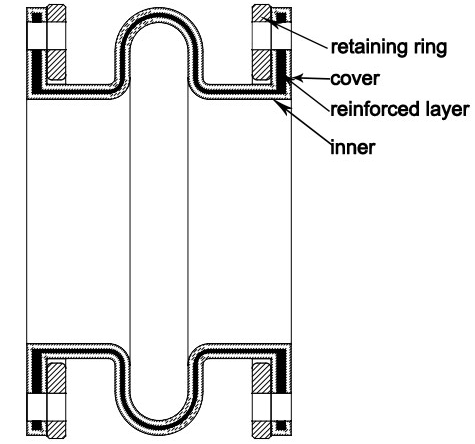

The spool type rubber joint is molded type, with a metal collar reinforced at the neck of the body. The ST stype uses a light reaining ring to support the integral flange. STF is filled arch, with 50% of the ST allowed movements, but it has 4 times spring rates than hollow arch.

| Specifications | I | II | III |

| Working Pressure Mpa (Kgf/Cm2) | 1Mpa (10) | 1.6 (16) | 2.5 (25) |

| Test Pressure | 1.5Mpa | 2.4Mpa | 3.75Mpa |

| Burst Pressure Mpa (Kgf/Cm2) | 3 (30) | 4.8 (48) | 5.5 (55) |

| Vacuum Kpa (Kgf/Cm2) | 53 (400) | 86(660) | 100 (750) |

| Materials | EPDM/NBR/SBR/NR | ||

| Diameter Range | DN15-DN600 (1/2″-24″) | ||

| Connection Method | FLANGETHREADCLAMP | ||

| Flanges Dimensions | DIN, EN,ANSI, BS, JIS and other standards | ||

| Applicable Medium | Air, compressed air, water, seawater, hot water, oil, acid, alkali etc. | ||

| Loading Port: | Qingdao, China | ||

| Shipment Terms: | FOB, CFR, CIF | ||

| Production Capacity: | 50000 set | ||

| Payment Terms: | L/C, T/T, D/P | ||

| Connection: | Flange, Thread | ||

| Flange Material: | Carbon Steel, Stainless Steel | ||

| Period of Delivery | about 21 working days | ||

|

SPOOL TYPE (ST) -American Standard ST |

||||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||||

|

Pipe Size |

O’all Length |

Flange OD |

Retaining Ring Thickness |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. (psi)-3,-4 |

Max Vacuum (in. of Hg)-5 |

|

|

Inch |

mm |

Inch |

Inch |

Inch |

Inch |

Inch |

Inch |

|||

|

2″ |

50 |

6″ |

6″ |

3/8″ |

7/16″ |

1/4″ |

±1/2″ |

19° |

150 |

26 |

|

2 1/2″ |

65 |

6″ |

7″ |

3/8″ |

7/16″ |

1/4″ |

±1/2″ |

15° |

150 |

26 |

|

3″ |

80 |

6″ |

7 1/2″ |

3/8″ |

7/16″ |

1/4″ |

±1/2″ |

13° |

150 |

26 |

|

4″ |

100 |

6″ |

9″ |

3/8″ |

7/16″ |

1/4″ |

±1/2″ |

10° |

150 |

26 |

|

5″ |

125 |

6″ |

10″ |

3/8″ |

7/16″ |

1/4″ |

±1/2″ |

8° |

150 |

26 |

|

6″ |

150 |

6″ |

11″ |

3/8″ |

7/16″ |

1/4″ |

±1/2″ |

6° |

150 |

26 |

|

8″ |

200 |

6″ |

13 1/2″ |

3/8″ |

11/16″ |

3/8″ |

±1/2″ |

6° |

150 |

26 |

|

10″ |

250 |

8″ |

16″ |

3/8″ |

11/16″ |

3/8″ |

±1/2″ |

5° |

150 |

26 |

|

12″ |

300 |

8″ |

19″ |

3/8″ |

11/16″ |

3/8″ |

±1/2″ |

5° |

150 |

26 |

|

14″ |

350 |

8″ |

21″ |

3/8″ |

11/16″ |

3/8″ |

±1/2″ |

4° |

150 |

15 |

|

16″ |

400 |

8″ |

23 1/2″ |

3/8″ |

11/16″ |

3/8″ |

±1/2″ |

4° |

150 |

15 |

|

18″ |

450 |

8″ |

25″ |

3/8″ |

11/16″ |

3/8″ |

±1/2″ |

3° |

150 |

15 |

|

20″ |

500 |

8″ |

27 1/2″ |

3/8″ |

13/16″ |

7/16″ |

±1/2″ |

3° |

150 |

15 |

|

24″ |

600 |

10″ |

32″ |

3/8″ |

13/16″ |

7/16″ |

±1/2″ |

3° |

150 |

15 |

|

SPOOL TYPE: FILLED ARCH (STF) -American Standard STF |

||||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||||

|

Pipe Size |

O’all Length |

Flange OD |

Retaining Ring Thickness |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. (psi)-3,-4 |

Max Vacuum (in. of Hg)-5 |

|

|

Inch |

mm |

Inch |

Inch |

Inch |

Inch |

Inch |

Inch |

|||

|

2″ |

50 |

6″ |

6″ |

3/8″ |

7/32″ |

1/8″ |

±1/4″ |

9.5° |

150 |

26 |

|

2 1/2″ |

65 |

6″ |

7″ |

3/8″ |

7/32″ |

1/8″ |

±1/4″ |

7.5° |

150 |

26 |

|

3″ |

80 |

6″ |

7 1/2″ |

3/8″ |

7/32″ |

1/8″ |

±1/4″ |

6.5° |

150 |

26 |

|

4″ |

100 |

6″ |

9″ |

3/8″ |

7/32″ |

1/8″ |

±1/4″ |

5° |

150 |

26 |

|

5″ |

125 |

6″ |

10″ |

3/8″ |

7/32″ |

1/8″ |

±1/4″ |

4° |

150 |

26 |

|

6″ |

150 |

6″ |

11″ |

3/8″ |

7/32″ |

1/8″ |

±1/4″ |

3° |

150 |

26 |

|

8″ |

200 |

6″ |

13 1/2″ |

3/8″ |

11/32″ |

3/16″ |

±1/4″ |

3° |

150 |

26 |

|

10″ |

250 |

8″ |

16″ |

3/8″ |

11/32″ |

3/16″ |

±1/4″ |

2.5° |

150 |

26 |

|

12″ |

300 |

8″ |

19″ |

3/8″ |

11/32″ |

3/16″ |

±1/4″ |

2.5° |

150 |

26 |

|

14″ |

350 |

8″ |

21″ |

3/8″ |

11/32″ |

3/16″ |

±1/4″ |

2° |

150 |

15 |

|

16″ |

400 |

8″ |

23 1/2″ |

3/8″ |

11/32″ |

3/16″ |

±1/4″ |

2° |

150 |

15 |

|

18″ |

450 |

8″ |

25″ |

3/8″ |

11/32″ |

3/16″ |

±1/4″ |

1.5° |

150 |

15 |

|

20″ |

500 |

8″ |

27 1/2″ |

3/8″ |

13/32″ |

7/32″ |

±1/4″ |

1.5° |

150 |

15 |

|

24″ |

600 |

10″ |

32″ |

3/8″ |

13/32″ |

7/32″ |

±1/4″ |

1.5° |

150 |

15 |

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

Jessy Lin

-

WeChat

Ellen Zhang